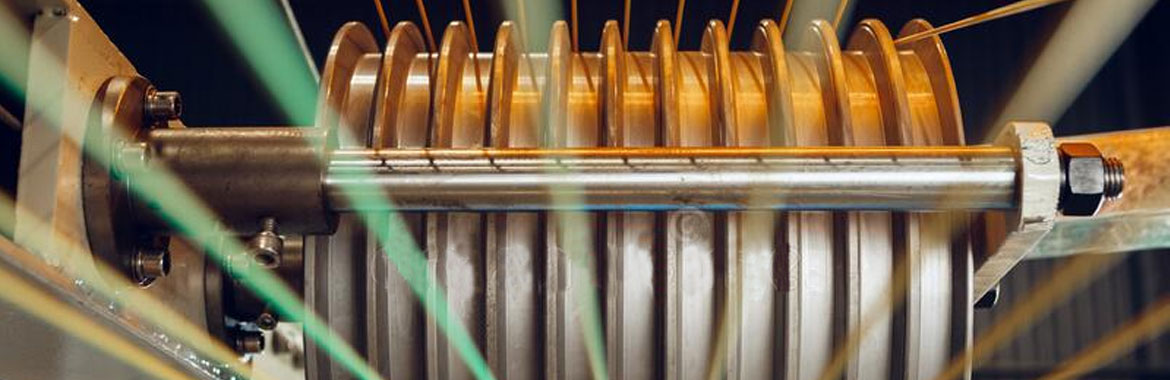

Apar’s Conductor & Cable manufacturing capabilities

- Two manufacturing plants spread over 200,000 sq meters situated 150km from the Mumbai sea-port.

- All our manufacturing plants are certified to ISO 9001, ISO140001 & OHSAS 45001.

- In-house compounding facility to make polymeric compounds and blends (PCP, EPR, CSP, EVA & EPDM) for insulation and sheathing of cables.

- Three electron beam irradiation facilities, 1.5MeV, 2.5MeV and 3.5MeV, respectively.

- Leveraging the best in class and state of art, plant machinery and equipment . Apar’s wire drawing capability boost of Niehoff (Germany) set up and the electroplating facility comes from Otomec Italy.

- Royale USA and Scholz/ Supermac CCV (Dry Core Dry Cool) Line for XLPE cables upto 66kV and extruders from Troestar, Coverna, royale, Rosendahl and Maillefer.

- Continuous improvement methodology implemented across our manufacturing plants comprises a blend of Kaizen and Lean principles, to continually reduce waste, improve efficiency and quality, minimize defects and increase through put.

- Annual production capacity in excess of 30000 MT tonnes & 10000 MT for Aluminium and Copper respectively.

Our Partners

Our Manufacturing Partners

Apar Industries, established in 1958, is one of the leading certified power cable manufacturers in the Asia Pacific region.

APAR manufacturing infrastructure encompasses, nine plants on the western seaboard of India spread across 250,000 SqM. Apar plants are ideally located at Umbergaon & Khattalwada ; Around 150 Km from Mumbai Sea Port making it easier for export shipments. Both facilities are equipped with state of the art, advanced manufacturing equipment, including multiple e-Beam facilities for irradiation cross linking polymers and testing infrastructure.

With a sales and distribution presence in over 100 countries, Apar is Asia Pacific’s largest, vertically integrated producer of Aluminium Rod, Alum Alloys including 8000 series Rods and rated amongst the top 3 conductor manufacturers in the world.